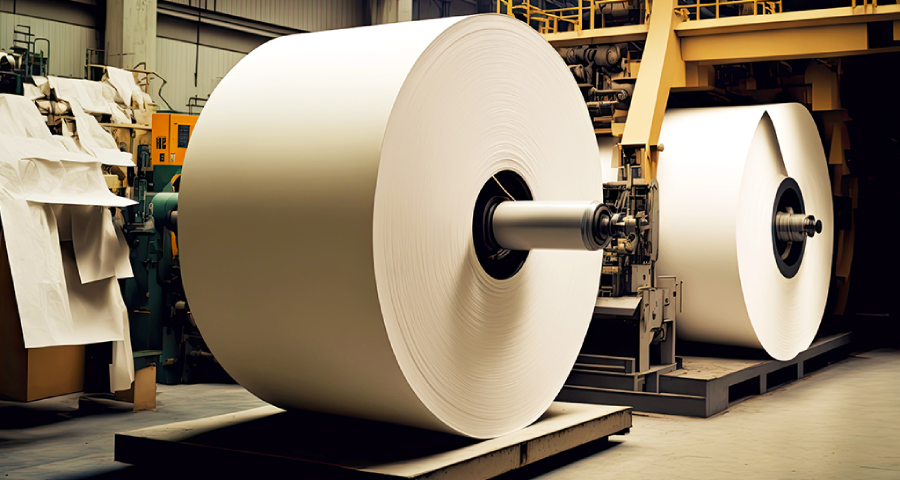

The Impact of Rollers on the Paper Industry

December 15,2023

Industrial Rollers have created a great impact on the paper industry. Products made of paper have attracted the attention of consumers and manufacturers. At present, every consumer product relies on some form of paper. Thus, Paper Mill Rollers have become an inevitable component.

It is integrated into different stages of the paper production process. Hence, the industry significantly relies on rollers to attain seamless functioning and enhance productivity. Prone to tearing is a typical nature of paper.

Hence, the product has to be transferred between the stages carefully. The quality of the paper has to be ensured, which indirectly depends on the functionality of the rollers.

Certain factors influence the positive or negative impact on the paper industry created by the rollers. This article is drafted to provide useful information.

Chemical Resistance

The chemical composition applied for producing paper is different, and the intensity of chemicals differs with the stage of paper production. The industrial rollers installed have to withstand the chemical reaction that takes place during the manufacturing process.

The paper is a thin medium, and it is technically challenging to process with the aid of conventional conveyors. Rollers have made it possible, and it allows the paper to get processed on both sides.

The point of contact between the paper and the roller happens it at a single junction. The chemicals have to be resisted by the roller without reacting and creating a by-product.

In most cases, depending on the manufacturing condition, the industrial rollers of the chemically resisting materials are chosen.

Dewatering

Water and chemicals are the composite materials used in the manufacturing of a paper product. Those materials are squeezed out during the production process to obtain the product of the desired form. Industrial Rollers are the components that are most commonly used in the dewatering process.

Though some other methods and techniques prevail, rollers are considered to be cost-effective. In addition, the desired quality of the paper can be achieved when processed with the aid of industrial rollers.

Henceforth, this component has been influencing the paper industry ever since its introduction in the industry. There are projects where the paper product has to be processed with the moisture content.

Industrial rollers allow the manufacturer to produce the paper with the defined content. Also, paper mill rollers withstand the strain and pressure during the production process.

Working Condition

Paper is produced at a very high temperature, and the process differs between stages. The rollers have to deliver their functionality irrespective of the working conditions. The paper undergoes various changes when processed to obtain the product of the desired technical details and properties.

Other than industrial paper mill rollers, the equipment integrated into the process is exclusive to the production stages. Moreover, the working environment has to be tailored for an efficient and highly productive paper manufacturing process.

To achieve this, it is challenging. Why so? Because it primarily depends on the supply chain management and the production layout. Industrial rollers possess higher value and are greatly suitable to line up in the assembly line to produce paper.

The material type of rolls is chosen precisely based on the working environment, and it can be tailored to the specific needs. Industrial rollers are an undeniable machine in the paper industry.

Coefficient of Friction

Friction is a factor that is directly related to production capacity. The paper that is processed on different machines relies on industrial rollers.

The outer surface of rollers is ensured to possess the required finish to transfer the paper with friction.

Rollers are the conveying medium irrespective of the type of equipment integrated for production. The rotational speed can be programmed based on the production stage, which adds value to the quality of the paper produced.

The rollers retain the friction without being influenced by the chemical composition.

Process

The production of paper material involves drying and calendaring to obtain the finished product. These processes involve the use of industrial rollers.

The pressure and stress are applied to the rollers to achieve the paper of the desired quality.

The process becomes complex and inefficient if the rollers deliver their purpose with a dip in functionality. Periodic maintenance is planned prior to eliminating the chance of malfunction.

Conclusion

We hope this article has provided you with valuable information on the impact created by industrial rollers. The paper industry and paper mill rollers are interconnected. Choosing the best quality rollers elevates productional capability and turnover. Venus Rubbers is one of the prominent manufacturers of industrial rollers exclusively for the paper industry, offering various models.

Latest Posts

The Impact of Rollers on the Paper Industry

December 15,2023

Importance of Rubber Rollers in the Textile Industry

December 22,2022